Enter into our laboratory,enter into the inside of our lights,know more,more interested,more prefer,That is what branding is all about,charm of brand.

Testing whether the grounding resistance meets the requirements of the standard and promise the safety of lights to humans.

The function of grounding is that when the insulation of the lights fails, the leakage current will be directly goes into the earth through the ground wire and will not hurt human body. Therefore, the smaller grounding resistance, much safer.

How to test the grounding resistance?

We test under Europe standard:the input current 12A, testing time 5 seconds,if the grounding resistance ≦ 500m,it is qualified.

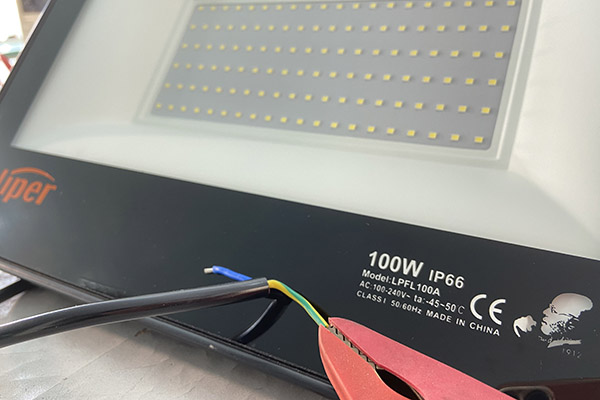

Let’s use the red clip connect the grounding wire.

the black clip connect the light’s body which is easily get electricity,we usually choose the screw.

Then start to test.

Now,lets check the grounding resistance value only 23MΩ,definitely totally safe.

There are three points important to resistance:

1. The material of the external wire,the copper wire, which has strong conductivity and low resistance

2. The cross-section of the wire, the larger,the smaller resistance,according to the IEC standard, the cross-section of the wire need ≥ 0.75 square millimeter,we totally meet the standard and higher than the market.

3. The chip board,there is a part which connect the ground wire,must need tighten the screw,or will lose conductivity.

Thanks reading this article,we are liper,we are LED light manufacturer,we are not only make the world more energy saving,also keep your safe.

See you next time.

Post time: Sep-29-2020